Tratamientos de aguas residuales, purines y digestatos

- Home

- Tratamientos de aguas residuales, purines y digestatos

El desafío del Agua en el mundo

The water is a limited resource and is essential for life.

Promoting the sustainable management of water resources it is important to protect and conserve these resources in an effective way.

Agreement of Paris

Groundwater directive

The Water Framework directive (WFD)

ODS

ODS 6: Agua Limpia y Saneamiento ODS 15: Vida de Ecosistemas Terrestres ODS 14: Vida Submarina

Problems in water purification traditional

High energy and maintenance costs

High content of organic matter and nutrients

Bad smells

High emissions of CO2 and other GHG emissions

How do we eliminate the sludge?

In almost all sewage treatment plants, traditional, after the pretreatment and primary treatment would the treatment secondary, for which are used bioreactors with aerobic bacteria, it is necessary to use compressors to inject the oxygen in need of these bacteria, which leads to a large consumption of energy.

In these reactors due to the bacterial activity is apparent a lot of CO2 and other Greenhouse Gases.

Además, el efluente todavía lleva disuelta una alta concentración de nutrientes (Ny P), which produce the well-known effects of eutrophication en las agua naturales

Por último el proceso genera unos residuos en forma de lodos que contienen una mezcla de materia orgánica, microorganismos, sólidos suspendidos y otros contaminantes cuya gestión plantea desafios ambientales y operativos.

Microalgae for wastewater treatment

-80% energy and a -75% maintenance

90% removal BOD and N+P

No bad odors

sin emisionesde CO2 y otros GEI

Sludge recoverable

One of the key aspects of our technology is the reduction of energy consumption. In the treatment of waste water, about 60-70% of the consumption of energy is produced by the need to provide oxygen for the growth of aerobic bacteria in the biological reactor. With our technology of debugging are the microalgae which provide the oxygen, so that starting, we already have a large energy savings.

The biological reactors allow for the growth of microalgae, that take advantage of the energy from the sun to perform secondary treatment and also tertiary.

To perform photosynthesis, microalgae assimilate CO2 and dissolved nutrients in the water and give off oxygen, allowing the concentration of oxygen is high, and to promote the growth of aerobic bacteria. They form therefore a consortium bacteria and algae are metabolized in the liver most of the nutrients in the wastewater, highlighting a nitrogen and phosphorus removal of over 85% in most cases.

Due to the oxygen is produced by the microalgae does not require external supply of oxygen, so the energy costs and maintenance are greatly reduced.

In addition, the high concentration of oxygen makes this process does not detach bad odors.

In these systems occurs a effluent quality for use in irrigation and a biomass with a remarkable value.

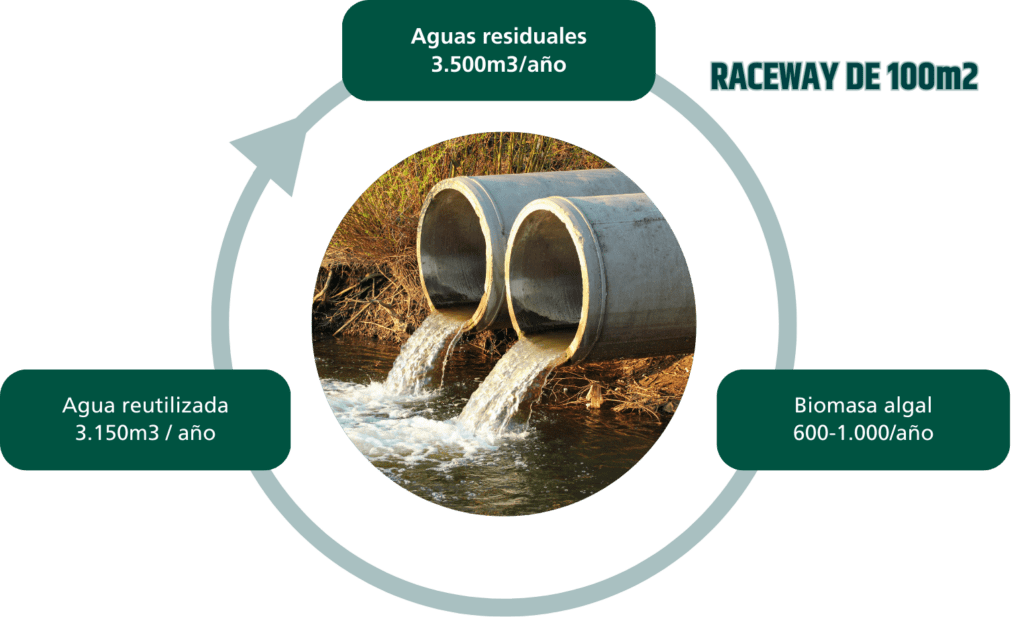

Example of treatment of wastewater

Photobioreactor 100m2

3500 m3 / year

Un reactor de 100m2 (50m x 2m) tiene capacidad para gestionar 3500m3 de aguas residuales al año.

Equivalente a una población de 120 habitantes.

You are going to be able to reuse the 90% of this water for the work of irrigation or cleaning.

Likewise, you are going to get between 600 and 1000kg biomass highly revalorizable.

Cost of treatment

Plant experimental CENTER (Centro Experimental New Technologies in the Water)

For the treatment of wastewater.

- Population equiv.: 250 habitants

- Flow treaty: 20-40 m3 / day

- Tank Imhoff: 12.4 m3

- Superf. bioreactor: 380 m2

- Depth: 0.3 m

- Reduction DBO: 85-90%

- Removal total N: 85-95%

- Removal P total: 85-95%

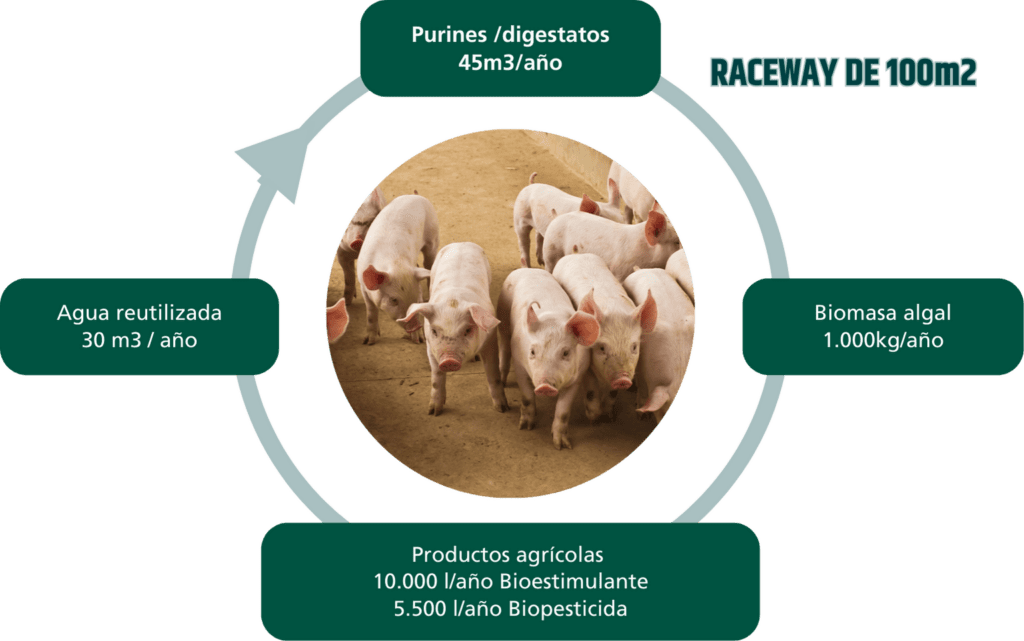

Treatment of pig manure

Purines, which are liquid waste generated by the rearing of animals, contain high concentrations of nitrogen and phosphorus, as well as other organic compounds.

The efficiency of the microalgae in the treatment of pig manure lies in its ability to absorb nutrients, produce biomass, oxygenate the water and recycle nutrients, offering an innovative and sustainable solution for waste management in the livestock industry.

A raceway of 100m2 (50 mx 2m) has capacidada to manage 45m3 of manure a year. Here you will be able to recover 30 m3 of water per year and you are going to get 100 kg of biomass algal which could get 10,000 liters of biostimulant and 5,500 litres of biopesticide.

Applications of the biomass of algal

The biomass of algal obtained after the water treatment with microalgae has valuable applications.